Process design

Benefit from maximum productivity

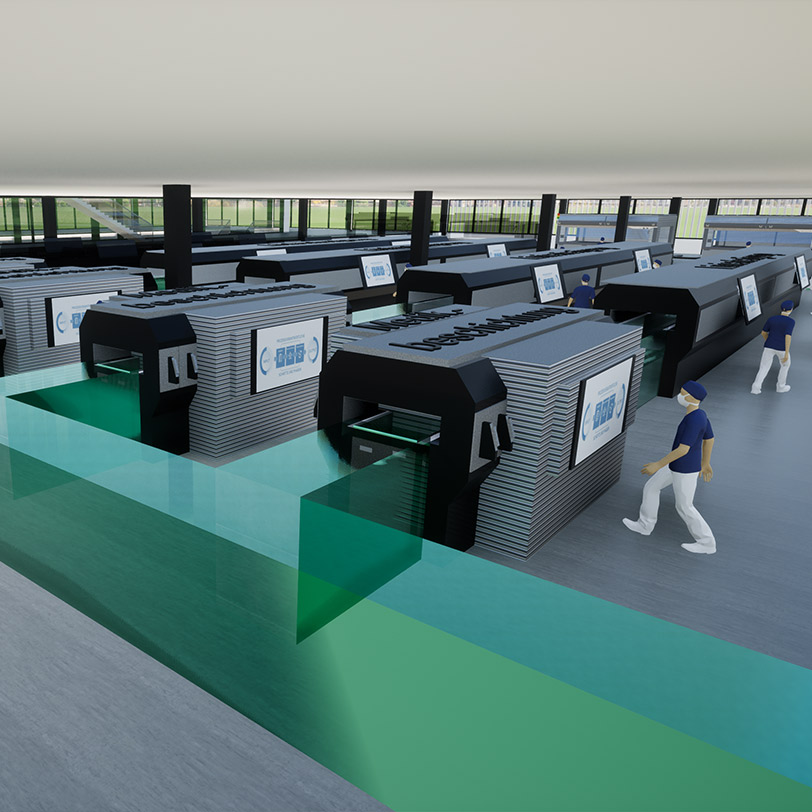

When we redesign your processes, our goal is to implement the ideal process for your production. Our job is to balance quality, efficiency, sustainability and employee acceptance. Our approach is systematic. We use in-depth process analysis to determine production parameters, which we then use to optimize the process in detail along the value chain.

We can do this because our specialists have the appropriate engineering know-how. We plan and implement your processes with a cost-benefit ratio that protects your margins and strengthens your competitive position.

Our performance

- holistic process analysis

- sound process design and optimization

- process engineering and evaluation of techology

- design and selection of machinery and equipment

- Six Sigma and lean methods

- Standardization of process flows

- capacity planning and process dimensioning

- Calculaton of optimal batch sizes

- Integration of manual work and automation

- calculation of manufacturing costs