Logistics

Keep everything moving in your factory

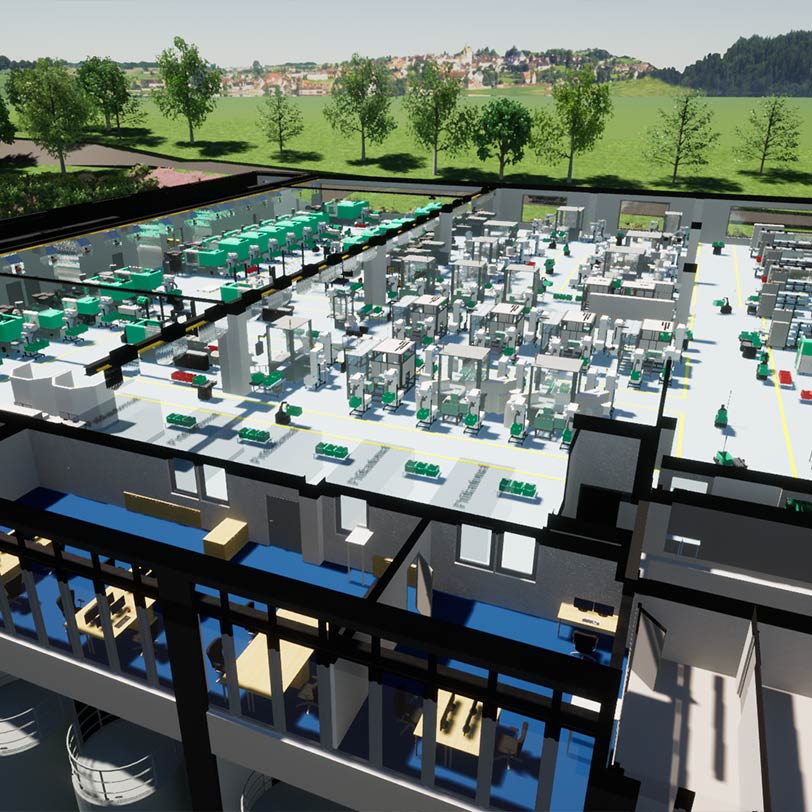

Only when production and logistics go hand in hand, the dynamics and efficiency of your value chain are right. In order for this to succeed, we tailor your logistics system, including all processes, exactly to your production. Ultimately, it's about timing. Therefore, that in every production or Processing step, the required raw materials, materials or pre-products are available.

We think and design your logistics end-to-end, from material or Raw material receipt to the outgoing goods. We plan each intermediate step in such a way that machine downtime and time losses are avoided or minimized. In this way, we ensure that everything that is needed in the production process is in the right place at the right time. An important point is the coordination between the digital flow of information, for example via an ERP system, and the physical material flow.

Our performance

- Planning and control of the entire value creation process

- Static data analysis and dynamic simulation of process flows

- Conception of an optimized material flow

- Development of transport and storage system solutions

- Coordination of manufacturing and logistics processes

- Consideration of the information flows parallel to the logistical chain but contrary to the material flow

- Consideration of the recycling cycles

- Transformation of logistics strategies

Your benefit

- Layout synchronizes material and information flow

- Lean and efficient E2E supply chain (end-to-end)

- Coordinated economic transport and storage systems

- Sustainable logistics concepts across the entire value chain

- Scalable and flexible logistics and production processes

- Connection/integration of ERP and MES systems

- Higher sustainability through resource efficiency